SDA Series aluminium alloy akting tipe ipis pneumatic baku silinder hawa kompak

Panjelasan Produk

Silinderna nyaéta desain ipis sareng diménsi sadayana leutik, anu cocog pikeun waktos anu terbatas. Tekanan kerjana biasana antara 0.1 ~ 0.9mpa, anu ngagaduhan efisiensi kerja anu luhur.

Silinder séri SDA gaduh kinerja sealing anu dipercaya sareng ciri gerakan anu mulus. Ieu adopts téhnologi manufaktur-precision tinggi pikeun mastikeun tightness jeung akurasi silinder nu. Dina waktos anu sami, silinder dilengkepan alat panyangga, anu tiasa ngirangan dampak sareng bising nalika gerakan.

Spésifikasi Téknis

| Ukuran Bore (mm) | 12 | 16 | 20 | 25 | 32 | 40 | 50 | 63 | 80 | 100 |

| Modeu akting | Ganda Akting | |||||||||

| Média Gawé | Hawa Dibersihkeun | |||||||||

| Tekanan Gawé | 0,1 ~ 0,9Mpa (kg/cm) | |||||||||

| Tekanan Buktina | 1,35Mpa(13,5kgf/cm) | |||||||||

| Suhu Gawé | -5 ~ 70 ℃ | |||||||||

| Modeu panyangga | Jeung | |||||||||

| Ukuran Port | M5 | 1/8 | 1/4 | 3/8 | ||||||

| Bahan Awak | Aluminium Alloy | |||||||||

| Pindah sénsor | CS1-J | CS1-G CS1-J | ||||||||

Katerangan;Gigi SDA 100 atanapi 25 dina rod piston silinder, sareng huntu pikeun rod piston Ф 32

100≤ST<150, tur euweuh magnét, panjang silinder 10.

ST≥150, euweuh urusan nganggo atanapi tanpa magnét, panjang silinder 10.

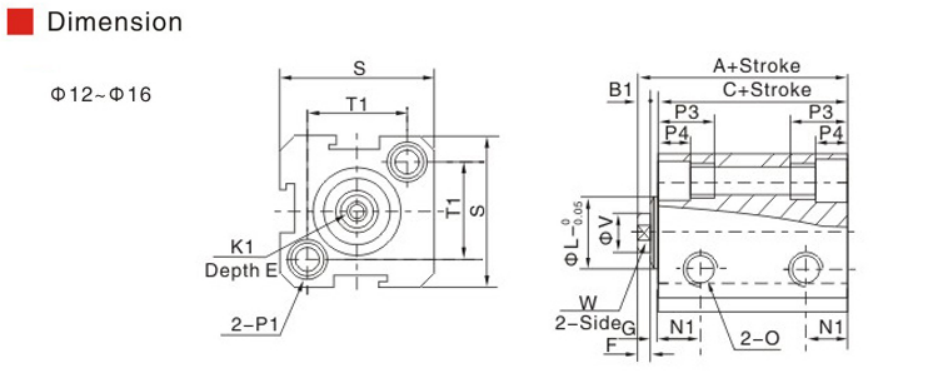

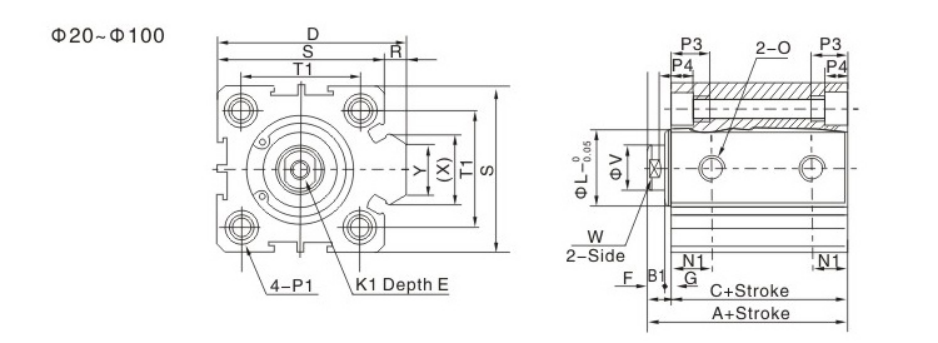

| Ukuran Bore (mm) | Tipe Standar | Tipe Magnét | D | B1 | E | F | G | K1 | L | N1 | N2 | O | ||

| A | C | A | C | |||||||||||

| 12 | 22 | 17 | 32 | 27 | / | 5 | 6 | 4 | / | M3X0.5 | / | 7.5 | 5 | M5X0.8 |

| 16 | 24 | 18.5 | 34 | 28.5 | / | 5.5 | 6 | 4 | 1.5 | M3X0.5 | 11 | 8 | 5.5 | M5X0.8 |

| 20 | 25 | 19.5 | 35 | 29.5 | 36 | 5.5 | 8 | 4 | 1.5 | M4X0.7 | 14 | 9 | 5.5 | M5X0.8 |

| 25 | 27 | 21 | 37 | 31 | 42 | 6 | 10 | 4 | 2 | M5X0.8 | 17 | 9 | 5.5 | M5X0.8 |

| 32 | 31.5 | 24.5 | 41.5 | 34.5 | 50 | 7 | 12 | 4 | 3 | M6X1 | 22 | 9 | 9 | G1/8 |

| 40 | 33 | 26 | 43 | 36 | 58.5 | 7 | 12 | 4 | 3 | M8X1.25 | 28 | 9.5 | 7.5 | G1/8 |

| 50 | 37 | 28 | 47 | 38 | 71.5 | 9 | 15 | 5 | 4 | M10X1.5 | 38 | 10.5 | 10.5 | G1/4 |

| 63 | 41 | 32 | 51 | 42 | 84.5 | 9 | 15 | 5 | 4 | M10X1.5 | 40 | 12 | 11 | G1/4 |

| 80 | 52 | 41 | 62 | 51 | 104 | 11 | 20 | 6 | 5 | M14X1.5 | 45 | 14.5 | 14.5 | G3/8 |

| 100 | 63 | 51 | 73 | 61 | 124 | 12 | 20 | 7 | 5 | M18X1.5 | 55 | 17 | 17 | G3/8 |

| Ukuran Bore (mm) | P1 |

| 12 | sisi ganda: Ф6.5 ThreadM5 * 0.8 Ngaliwatan liang Ф4.2 |

| 16 | sisi ganda: Ф6.5 ThreadM5 * 0.8 Ngaliwatan liang Ф4.2 |

| 20 | sisi ganda:Ф 6,5 ThreadM5 * 0,8 Ngaliwatan liang Ф4.2 |

| 25 | sisi ganda:Ф 8.2 ThreadM6 * 1.0 Ngaliwatan liang Ф4.6 |

| 32 | sisi ganda:Ф 8.2 ThreadM6 * 1.0 Ngaliwatan liang Ф4.6 |

| 40 | sisi ganda: Ф10 ThreadM6 * 1,25 Ngaliwatan liang Ф6.5 |

| 50 | sisi ganda: Ф11 ThreadM6 * 1,25 Ngaliwatan liang Ф6.5 |

| 63 | sisi ganda: Ф11 ThreadM8 * 1.25 Ngaliwatan liang Ф6.5 |

| 80 | sisi ganda: Ф14 ThreadM12 * 1.75 Ngaliwatan liang e:Ф9.2 |

| 100 | sisi ganda: Ф17.5 ThreadM14 * 12 Ngaliwatan liang Ф11.3 |

| Ukuran Bore (mm) | P3 | P4 | R | S | T1 | V | W | X | Y |

| 12 | 12 | 4.5 | / | 25 | 16.2 | 6 | 5 | / | / |

| 16 | 12 | 4.5 | / | 29 | 19.8 | 6 | 5 | / | / |

| 20 | 14 | 4.5 | 2 | 34 | 24 | 8 | 6 | 11.3 | 10 |

| 25 | 15 | 5.5 | 2 | 40 | 28 | 10 | 8 | 12 | 10 |

| 32 | 16 | 5.5 | 6 | 44 | 34 | 12 | 10 | 18.3 | 15 |

| 40 | 20 | 7.5 | 6.5 | 52 | 40 | 16 | 15 | 21.3 | 16 |

| 50 | 25 | 8.5 | 9.5 | 62 | 48 | 20 | 17 | 30 | 20 |

| 63 | 25 | 8.5 | 9.5 | 75 | 60 | 20 | 17 | 28.7 | 20 |

| 80 | 25 | 10.5 | 10 | 94 | 74 | 25 | 22 | 36 | 26 |

| 100 | 30 | 13 | 10 | 114 | 90 | 25 | 22 | 35 | 26 |